耐候性試驗

Weathering Testing

咨詢熱線

18566398802ASTM D4329-05

ASTM D4329-05標準介紹

塑料熒光紫外線暴露測試的標準測試方法:

本測試方法規定了依照G151和G154測試方法對塑料進行熒光紫外線暴露測試的具體程序和測試條件。

ASTM D4329-05英文版本

This standard is issued under the fixed designation D 4329; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope*

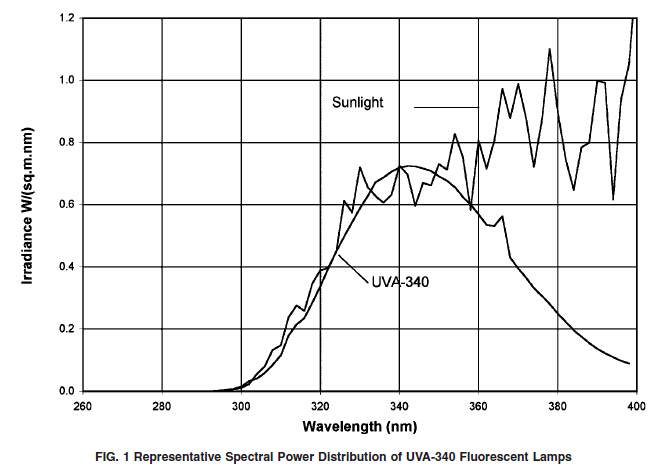

1.1 This practice covers specific procedures and test conditions that are applicable for fluorescent UV exposure of plastics conducted in accordance with Practices G 151 and G 154. This practice also covers the preparation of test specimens, the test conditions best suited for plastics, and the evaluation of test results.

1.2 The values stated in SI units are be regarded as standard. The values given in brackets are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

NOTE 1—This practice is technically similar to ISO 4892-3.

2. Referenced Documents

2.1 ASTM Standards:

D 3980 Practice for Interlaboratory Testing of Paint and Related Materials

D 5870 Practice for Calculating Property Retention Index of Plastics

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G 113 Terminology Relating to Natural and Artificial Weathering Tests of Nonmetallic Materials

G 141 Guide for Addressing Variability in Exposure Testing on Nonmetallic Materials

G 147 Practice for Conditioning and Handling of Nonmetallic Materials for Natural and Artificial Weathering Tests

G 151 Practice for Exposing Nonmetallic Materials in Accelerated Test Devices That Use Laboratory Light Sources

G 154 Practice for Operating Fluorescent Light Apparatus for UV Exposure of Nonmetallic Materials

G 169 Guide for Applications of Basic Statistical Methods to Weathering Tests

G 177 Tables for Reference Solar Ultraviolet Spectral Distributions: Hemispherical on 37 Degree Tilted Surface

2.2 ISO Standard:

ISO 4892-3 Plastics—Methods of Exposure to Laboratory

Light Sources—Part 3, Fluorescent UV Lamps

2.3 SAE Standard:

SAE J2020 Accelerated Exposure of Automotive Exterior Materials Using a Fluorescent UV and Condensation Apparatus

3. Terminology

3.1 The definitions in Terminology G 113 are applicable to this practice.

4. Significance and Use

4.1 The ability of a plastic material to resist deterioration of its electrical, mechanical, and optical properties caused by exposure to light, heat, and water can be very significant for many applications. This practice is intended to induce property changes associated with end-use conditions, including the effects of sunlight, moisture, and heat. The exposure used in this practice is not intended to simulate the deterioration caused by localized weather phenomena, such as, atmospheric pollution, biological attack, and saltwater exposure.

(Warning—Variation in results may be expected when operating conditions are varied within the accepted limits of this practice. Therefore, no reference to the use of this practice should be made unless accompanied by a report prepared in accordance with Section 8 that describes the specific operating conditions used. Refer to Practice G 151 for detailed information on the caveats applicable to use of results obtained in accordance with this practice.)

NOTE 2—Additional information on sources of variability and on strategies for addressing variability in the design, execution, and data analysis of laboratory-accelerated exposure tests is found in Guide G 141.

4.2 Reproducibility of test results between laboratories has been shown to be good when the stability of materials is evaluated in terms of performance ranking compared to other materials or to a control.5,6 Therefore, exposure of a similar material of known performance (a control) at the same time as the test materials is strongly recommended. It is recommended that at least three replicates of each material be exposed to allow for statistical evaluation of results.

溫馨提醒:本ASTM D4329-05可能存在更新的版本,建議尋找ASTM D4329-05的發行商確認。

紫外線老化箱

紫外線老化箱 粵公網安備 44060402000067號

粵公網安備 44060402000067號